DIN24255/ ISO9908 Standard Long Life Horizontal End Suction Centrifugal Pump for Agriculture

This pump is brand new, unique and innovation industrial pumps designed in compliance with DIN24255 and ISO9908 standards, with an energy efficiency index of more than MEI 0.4/0.7, satisfying EU MEI requirements.

Product Series :

EK SeriesApplicable Standard :

DIN24255 and ISO9908 StandardCapacities :

4~1584m3/hHeads :

5~150mInlet and outlet diameter: :

DN32~300mmSpeed(r/min) :

1450rpm/ 2900rpm; 1750rpm/ 3500rpmMax. Working Pressure :

1.0MPa (standard); 1.6MPa(on special request)Temperature :

-10~85℃(Standard); 85~105℃(on Special Request)Long Life Horizontal End Suction Centrifugal Pump for Agriculture

This new industrial end suction pumps are capable of meeting the needs of customers in major industrial markets with options of various material configurations. This pump with modular design, are suitable for various application scenarios and meet the rigorous industrial needs.

Main Features

Medium Temperature:

-10℃~85℃ (standard)

85~105℃ (on special request)

Working Pressure:

1.0 MPa (standard)

1.6 MPa (on special request)

Flange: DIN2501 PN16 GB/T17241.6 PN1.6 (ANSI, JIS, AS...)

Operating Data

Discharge Size: DN32~300mm

Power: 0.55~315KW

Head: 5~150m

Flow Rate: 4~1574m3/h

Enhanced Industrial Adaptability

The diameter is extended to DN300 and flow rate is increased up to 1584m3/h.

With two models of PN10 &PN16, the casing and impeller are available in a variety of material combinations to satisfy different industrial needs.

The pump provided multiple bearing and sealing options, as well as sealing and flushing solutions for specific application needs.

The pumps adopt the optimized hydraulic design, which significantly reduces the noise generated by the water flow impact.

The rotor is designed with a thicker dimension, which increases the service life of the whole pump.

The pump casing is made of HT250, which improves the whole pump strength.

Optimize Investment

The pumps are designed in accordance with DIN24255 and ISO9908 standards to simplify the integration for existing systems.

The modular design optimizes spare parts management and reduces the delivery term.

Reduce Energy Consumption

MEI >0.4

The optimized hydraulic model effectively improves the efficiency (10% + efficiency improvement compared to previous EA series).

The pumps use intelligent control to optimize performance. Experiments have shown that 50% + energy saving would be achieved with frequency-converting control of the 11KW water pump.

The pumps are designed with a standard wearing ring configuration and stainless-steel sleeve design, which guarantees for a longer service life and reduces the downtime.

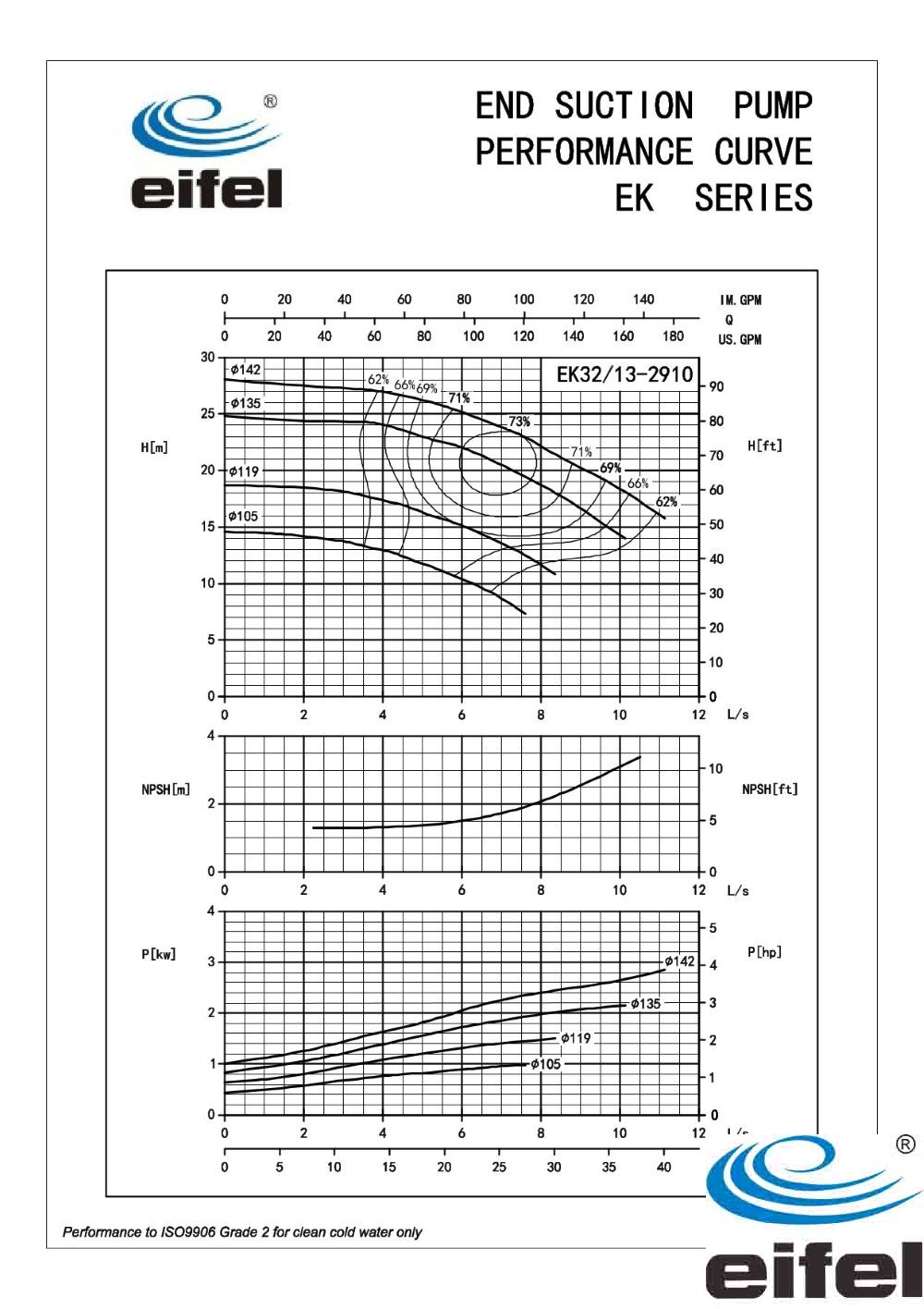

Performance Curve

Leave A Message

Scan to Wechat/Whatsapp :